Discover the Future of Green Packaging with Recycled PET Strapping Band Extrusion Line

After the NPE 2024 exhibition in the United States concluded, we gained significant insights that the customers have strong interest in the green energy economy within the American market. Many attendees expressed keen interest in products made from recycled materials, especially PET strapping bands produced by our innovative Recycled PET Strap Production Line.

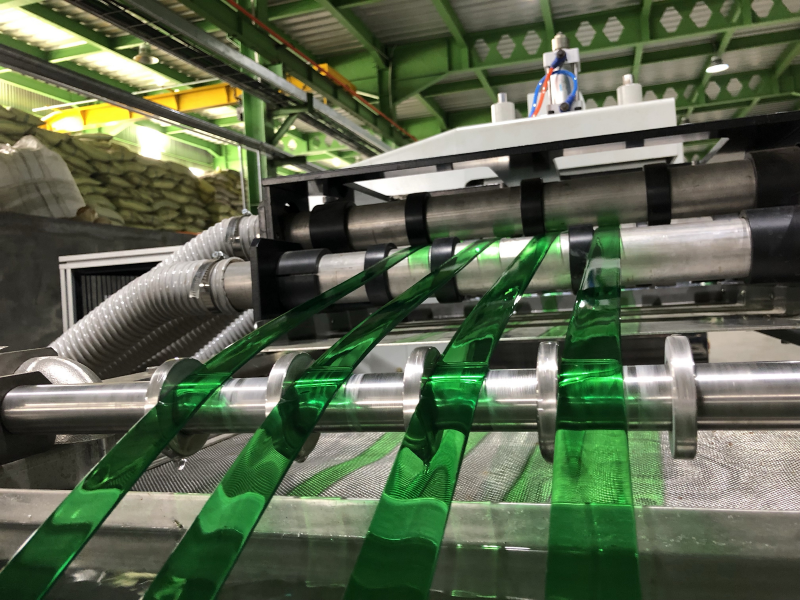

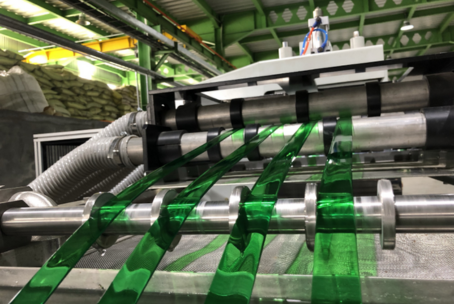

Eco-Friendly PET Strap Production Line

PLASCO, focusing on the "green energy circular economy," has developed an eco-friendly PET strap production line. This advanced extrusion line uses 100% recycled bottle flakes to produce PET strapping bands with high tensile strength and high elongation, which is an ideal replacement for traditional steel bands. These PET strapping bands align with the global consensus on "energy saving and carbon reduction" which are recognized internationally with the eco-friendly certification for packaging products.

Introducing the JC-SPET Series

The JC-SPET Series uses cutting-edge technology to produce PET strapping bands from 100% recycled PET flakes. These straps match steel in strength, ideal for securing bricks, tiles, cotton bales, and lumber, promoting both reliability and sustainability.

Key Features of the Recycled PET Strap Extrusion Machine

-

Cost-Effective Alternative to Steel Bands :

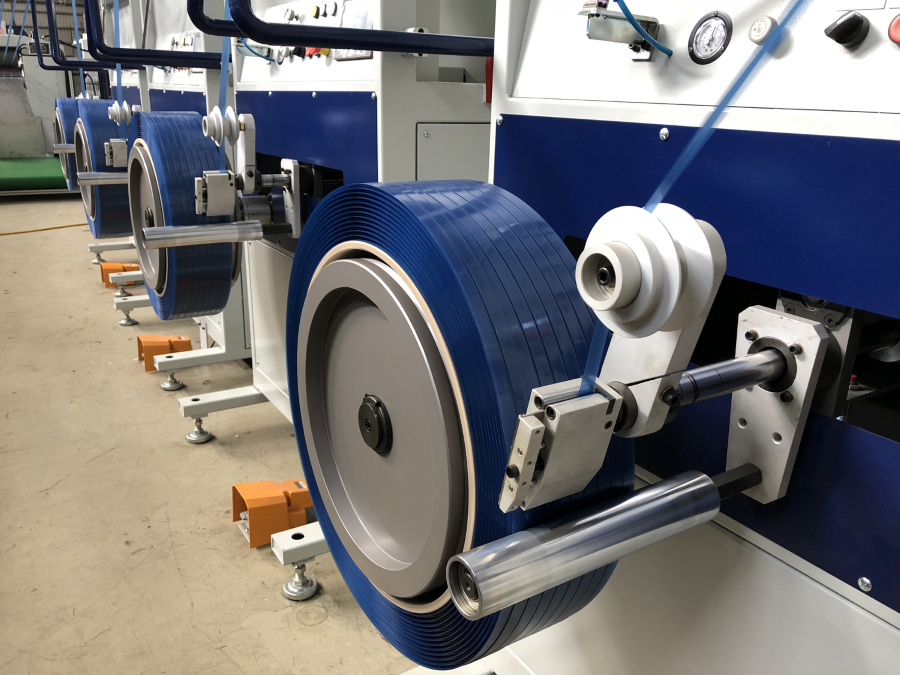

Using 100% recycled PET materials, the PET strapping bands offer tensile strength comparable to steel bands of the same specifications. Following the features of high strength and high toughness, they are used for machine-grade packing. PET strapping bands designed for automatic packaging are only 1/6 the weight of steel bands, providing a cost-effective alternative to traditional steel bands and manual-grade strapping bands.

-

Advanced Control to Reach Extrusion Stability & Precision :

The PET strap production line incorporates a precise temperature control system, a gear pump melt control system, and accurate drive units. These integrate into a comprehensive central monitoring and control system, ensuring ease of operation, practicality, and convenience. All monitored through HMI with remote capabilities.

-

User-Friendly Design :

The machinery has been continuously improved to enhance user-friendliness. The software design allows personnel from different countries to easily understand every operational aspect without extensive training. Smart industry capabilities ensure high performance while maintaining ease of operation and maintenance, distinguishing PLASCO in the market. The design incorporates fundamental concepts of mechanical operation, logical operation flow, and manufacturing processes. The automated machine operation, combined with a simple and clear central control interface, features a user-friendly mode and a built-in error alarm system. This ensures operators can easily access all information for safe and convenient operation.

-

Energy Efficiency :

PLASCO's machinery uses temperature control systems (SSR & SCR) for stable temperature regulation and a variable frequency drive system for transmission control. This achieves precise control of equipment operating speeds and optimal motor performance, reducing electricity consumption. The draw stand is equipped with a power regeneration device capable of collecting and converting regenerative energy into reusable electricity, achieving energy savings of up to 95%.

Explore the Specifications of PET Strapping Band Extrusion Lines to learn more about its capabilities and technical details.

Ready to embrace sustainable packaging solutions? Contact us today to inquire about how PLASCO’s Recycled PET Strapping Band Extrusion Line can transform your packaging operations.

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]