Enhancing Conveyor Belt Quality with PET Monofilament by Advanced Extrusion Machine

PET monofilament is one of the important materials for making conveyor belts, and the monofilament extrusion machine plays a crucial role to ensure the consistency in diameter and shrinkage of PET monofilament. In this article, we'll explore the key features of a pet monofilament extrusion line that can greatly improve the quality of conveyor belts. Manufacturers who want to maximize their production process and achieve exceptional performance need to understand and implement these features. So, let's dive into the world of pet monofilament extrusion and discover the key ingredients that can elevate the quality of conveyor belts!

Advantage of PET Monofilament for Conveyor Belt

There are the must-have features of PET Extrusion Machines, let's understand the process and the benefits of pet monofilament extrusion. In the manufacturing of conveyor belts, PET monofilaments are used to create the core structure. Conveyor belts consist primarily of interwoven binder warp, weft fiber, and warp fiber, and PET monofilament serves as a crucial weft fiber for reinforcing the belt's structure. Monofilament fabrics used for the reinforcement material in conveyor belts, offering numerous advantages over alternative reinforcement options, including:

-

Strength:

Monofilament fibers have high tensile strength, which allows conveyor belts to withstand heavy loads and provide reliable performance.

-

Durability:

Monofilament is resistant to wear and tear making it an ideal material for conveyor belts that need to endure frequent usage in harsh industrial environments.

-

Consistency:

Monofilament fibers have a uniform diameter and tensile strength, ensuring that the conveyor belt operates smoothly and evenly without any weak spots or inconsistencies.

-

Better Resistance to Heat and Moisture:

Monofilament is highly resistant to heat and moisture, common factors that can affect conveyor belt performance. Conveyor belts that use monofilament are less likely to warp or stretch due to temperature changes, and they are also less likely to absorb moisture, which can lead to belt degradation and failure.

-

Flexibility:

Monofilament fabrics can be woven into a variety of patterns, allowing for different levels of flexibility and strength in the belt.

-

Improved Tracking and Stability:

Conveyor belts that use monofilament have improved tracking and stability. Monofilament has low elongation, which means it has minimal stretch under load. It helps to prevent the belt from slipping or sagging, ensuring that it stays at the same place and transports materials efficiently.

-

Increased Longevity and Cost Savings:

The use of monofilament in conveyor belt construction can also increase the belt's longevity and save costs in the long run. Monofilament belts require less maintenance and replacement than traditional belts, reducing downtime and repair costs.

A PET monofilament extrusion line is a specialized machine that enables the precise production of these monofilaments.By utilizing advanced PET monofilament in conveyor belt manufacturing, manufacturers can enhance the overall quality and performance of their conveyor systems.

3 Must-Have Features for your PET Monofilament Making Machine

If your goal is to produce PET monofilament with precision quality, it is crucial to ensure that your extrusion machine incorporates 3 essential features.

-

Precise Temperature Control

When it comes to monofilament extrusion for conveyor belt production, achieving consistent and high-quality output requires several must-have features. One crucial feature is precise temperature control. Advanced temperature control systems in the extrusion machine allow for accurate regulation of the heating and cooling zones. This ensures optimal melting and solidification of the monofilament material, resulting in uniform filament diameter and enhanced product quality.

In the cooling stage, it is critical to maintain precise water temperature. To ensure consistent stable temperature of fabric in a cooling water bath, the temperature should be set between 60-80°C and maintain it with a heat exchanger. The water circulation is also crucial for evenly cooling the molten monofilament.

-

Reliable Filament Diameter Control

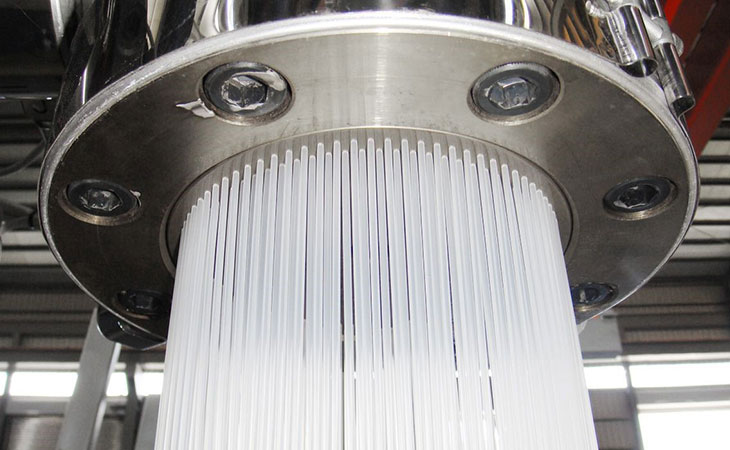

PET material requires the process of crystallization and drying at least 8 hours before producing, which avoids the fabric breaking easily in the process. The property dew point of monofilament should be -40°C. The extruder takes in the feed PET material, conveys and melts it evenly within screw and barrel, compresses it free of gas inclusion, homogenizes it, and finally feeds the melt under pressure and without pulsations to the spinning pump. The spinning pump is used for precise metering and transfer polymers in the production of monofilament, specially polyester specific of flowing. Coordinating with the HMI program, the pressure feedback provides the signal to automatically control, and ensure material comes out stable.

Moreover, maintaining a stable stretching ratio is crucial for producing monofilament with high strength and low elongation. To achieve an accurate stretching ratio, it is important to have smaller tolerances for roller diameter and line speed. The smaller the tolerance, the more precise the stretching ratio will be. This contributes to the overall dimensional consistency and performance of the monofilament.

-

Efficient Winding Systems

In conveyor belt production, a flange winder is typically used to wind each monofilament individually. During the winding process, it is important to maintain moderate tension on each spindle, which utilizes torque motors and inverters to control and stabilize the winder. It helps ensure uniform and appropriate tension at the bottom, middle, and surface of the spindle. Keeping consistent tension in the winding process, the winding system helps prevent irregular shapes of each spindle and enhances the overall quality of the monofilament.

Why You Should Work with Plasco for Your PET Monofilament Extrusion Line

In conclusion, monofilament materials, PET monofilament plays a significant role in enhancing the quality of conveyor belts. There are advantages such as strength, durability, resistance to heat and moisture, and improved conveying. To ensure the production of high-quality PET monofilament, it is crucial to have precise temperature control, reliable filament diameter control, and efficient winding systems. If you want to learn more about how monofilament enhances conveyor belt quality, and the essential features and trends for a monofilament extrusion machine, visit our website. Enhance the performance of your conveyor belts today at the PET Monofilament Extrusion Plant.

Know more Monofilament Extrusion Machine, please read also:

Nylon

Monofilament Extrusion Machine : Everything You Need to Know

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]