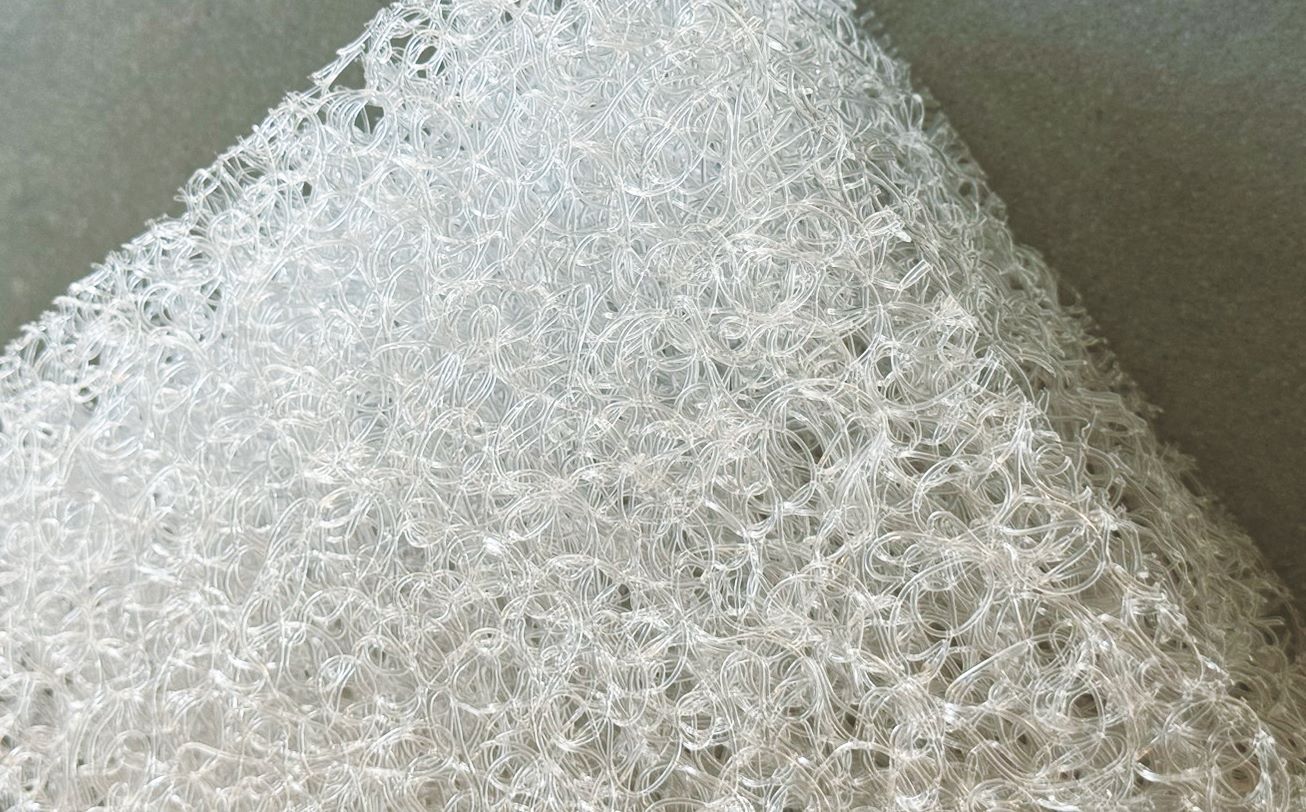

Innovative Plastic Extrusion : Revolutionizing 4D Mattress (Air Pad) Technology

Taiwan's medical system has consistently garnered global attention, with its success hinging on the availability of adequate medical resources.Since 2018, Taiwan has transitioned into an aging society, meaning that approximately 20 out of every 100 people are over the age of 65.This demographic shift has significantly increased the demand for medical resources, particularly in ensuring the provision of high-quality 4D mattresses.

PLASCO partnered with a renowned manufacturer and leveraged Japanese technology to co-develop a cutting-edge air pad extruder specifically tailored for the production of 4D cushions. This state-of-the-art device boasts the following key features:

1.Customized Extrusion Machinery:

The machinery specifications are tailored to different finished product sizes, allowing for the production of mattresses that meet various needs, shapes, and levels of softness, catering to each user's specific requirements.

2.Wide Range of Applications:

The extruder is versatile and suitable for a variety of products, including medical mattresses, chair cushions, backrests, and cushions for babies or pets.

3.High Production Flexibility:

It can produce a wide array of products, adjusting hardness and shape according to different product requirements through varying operating conditions.

4.Streamlined Process from Raw Material to Finished Products:

The extruder integrates key production line needs and peripheral equipment, enabling both input and output on the same production line. This improves overall production efficiency, reduces labor costs, and enhances competitiveness.

5.High Mechanical Efficiency:

The extruder can stably produce high-quality elastic fiber products, ensuring temperature stability, cooling efficiency, and a long product life cycle, meeting the stringent requirements of the medical industry.

Case Study

Over the past ten years, PLASCO has collaborated with well-known manufacturers to produce a variety of air pad-based products, with applications including:

- - Cushions (for office, wheelchair, or home use)

- - Pillows

- - Backrests

- - Pet mats

- - Various custom air cushions

These products have the following advantages:

- Pressure Relief:The soft and supportive air pad material releases pressure in all directions, preventing pressure concentration.

- Clean and Washable:Easy to maintain cleanliness at all times.

- Excellent Breathability:Made with special materials and designs that offer great breathability, anti-bacterial, and dust mite-resistant properties, especially perfect for humid weather.

- Material Environmentally Friendly:Free from chemicals, formaldehyde, and BPA.

These advantages bring significant business opportunities and profits to our customers, enabling them to meet the growing demand for high-quality, innovative air cushion products. By providing comfort, cleanliness, and environmental benefits, our cutting-edge Plastic Extrusion technology helps customers achieve greater satisfaction and loyalty, driving continuous growth and profitability in their respective markets.

Unleash the Potential of Plastic Extrusion:Explore the innovative features and detailed specifications of our Plastic Extrusion Line on our product page.

Looking for More? Explore our blog for a wealth of knowledge:

- Master Monofilament Extruders:Dive into our comprehensive guide for in-depth knowledge: Nylon Monofilament Extrusion Machine : Everything You Need to Know.

- Stay Ahead of the Curve:Discover the latest trends shaping the Monofilament Yarn Making Machine industry: Monofilament Yarn Making Machine : 4 Trends.

Need Assistance?Our experienced team is here to help! Reach out to us for any questions or specific requirements.

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]