How to Choose Monofilament Extruder ?

With the increasing demand for Monofilament Extruders, it's essential to understand the process of selecting the right machine to meet your specific requirements. The market offers a wide range of options, making it overwhelming to determine the most suitable equipment for your production needs. This article aims to break down the process of choosing the ideal Monofilament Extruder. By considering factors such as the type of products you manufacture, size and shape specifications, desired production capacity, as well as equipment interoperability and ease of use, we will help you make an educated decision. Read on to discover how you can streamline your production and enhance product quality by selecting the perfect Monofilament Extruder.

-

Capacity & Filament Dimension Requirements:

To ensure that your Monofilament Extruder meets your specific production requirements, it is crucial to determine the desired extrusion throughput. This includes identifying the required capacity, as well as the diameter of the monofilament. The production capacity is based on the filament diameter. By having a clear understanding of these key factors, you will be able to select a machine that can effectively meet your production demands.

-

Monofilament Material:

When it comes to monofilament, it's important to consider the various end uses and the specific properties required for each application. Different materials and polymers, such as polypropylene (PP), polyethylene (PE), nylon (PA), and polyester (PET), are commonly used in the production of monofilament. The production process itself varies depending on the material properties. Therefore, it is essential to ensure that the machine you choose is compatible with the specific material you will be working with.

-

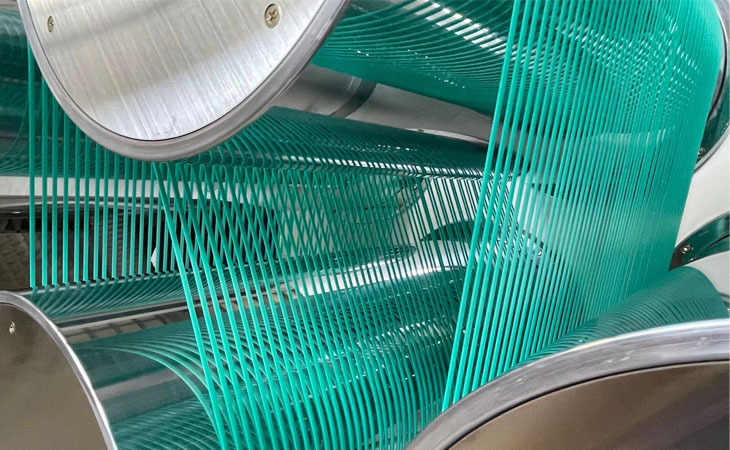

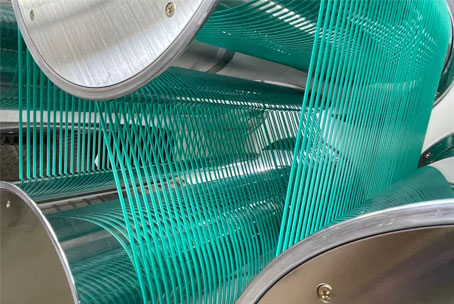

Machine Configuration:

Monofilament extrusion machines come in various configurations that are tailored to the specific properties and end uses of the final product. When configuring your monofilament extrusion line, it is essential to focus on filament quality, such as precision, strength, tension, and any other relevant conditions. Moreover, the factory environment must also be carefully considered, taking into account factors such as temperature, humidity, and available workspace.

-

Flexibility & Customization Design:

When selecting a monofilament extrusion machine, it's crucial to consider its flexibility in accommodating different diameters and features. Furthermore, it's essential to choose a machine not just with the ability to meet your customized design, but also one that incorporates modular components to accommodate varying specifications. By prioritizing flexibility and customization in your machine selection, you can adapt to changing market demands and produce monofilament products of varying types and sizes with ease.

Case study: Monofilament Aid-The Mosquito Nets Changing the World

Case study: Euronete: Leading in a Competitive Sea

Case study: Doubling Down: Meeting Growing Demand with PLASCO

-

Energy Efficiency:

It's important to account for its energy consumption and efficiency. Look for machine features such as variable speed drives, insulation, or energy-saving technologies that can help reduce energy wasting and operating costs over time. By choosing an energy-efficient machine, you can not only reduce your environmental impact but also save on long-term operational expenses. Prioritizing energy efficiency will not only benefit your bottom line but also contribute to a more sustainable production process.

-

Maintenance and Service:

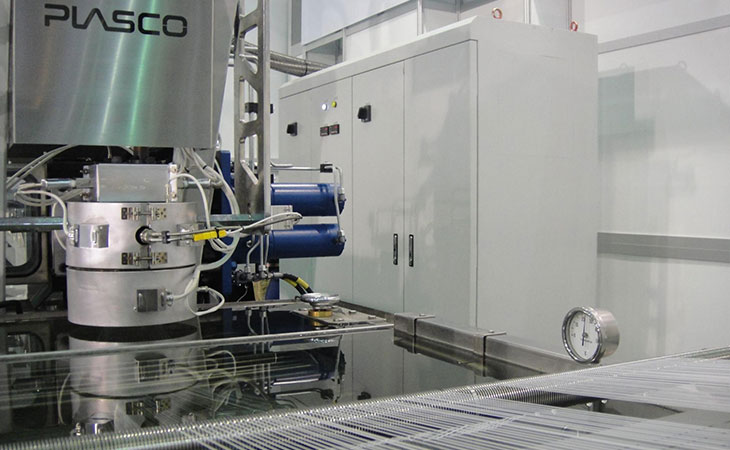

Assessing the maintenance needs of the extruder machine and ensuring the availability of required replacement parts are of utmost importance. It is advisable to look for a manufacturer that provides trustworthy customer assistance, timely technical support for installation and regular maintenance inspections, practical operational training, and an all-inclusive warranty that addresses any possible issues that may occur during the machine's lifetime. By prioritizing these considerations, you can have the assurance that you will have the necessary assistance and resources to uphold the machine's effectiveness, minimize any periods of inactivity, and guarantee a smooth and reliable production process.

PLASCO monofilament extrusion machines use the certificated quality and well-known brand machine electrical parts, which is easier to get the machine marts and shipping cost.

-

Cost:

Compare the prices of different monofilament extruders and assess the overall value they offer, considering factors such as features, quality, and support provided. It's also important to consider the long-term costs, including energy consumption, maintenance expenses, and potential productivity gains. By checking these factors, you can make an informed decision that balances affordability with the potential benefits of efficiency and productivity.

-

Safety and International Certification:

It is essential to ensure that the machine adheres to safety standards and complies with relevant regulations and international certifications specific to your industry, such as the Certificate of European Conformity. By prioritizing these factors, you can have peace of mind knowing that the machine is designed to operate safely and meets the necessary requirements and certifications in your industry.

By carefully evaluating these factors, you can make an informed decision and select the perfect Monofilament Extruder for your production requirements. Visit our Monofilament Extrusion Line now!

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]