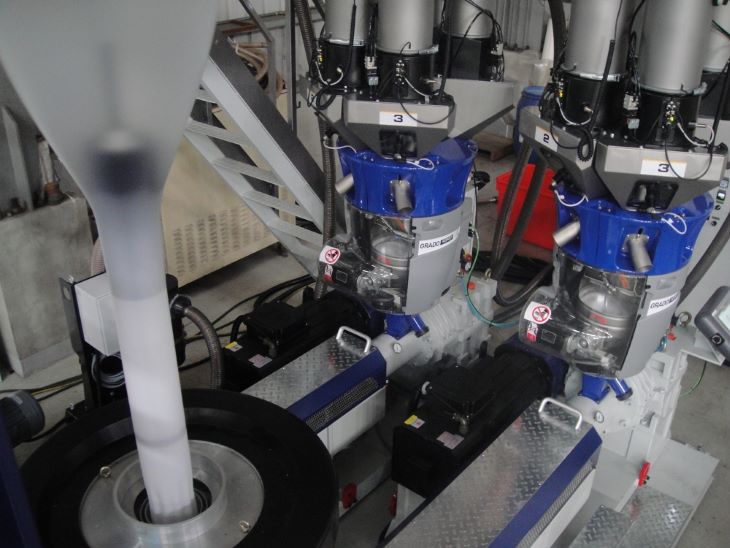

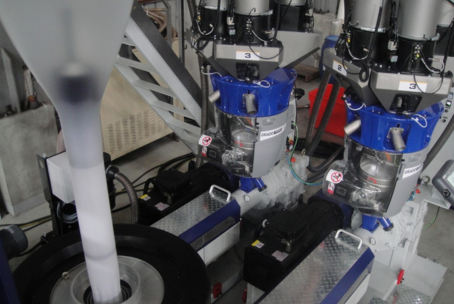

ABA Blown Film Extrusion : Boost Efficiency, Reduce Costs, Enhance Film Properties

The ABA blown film extrusion line is a versatile machine used in the plastic manufacturing industry for producing multi-layer films. This extrusion line is particularly renowned for its ability to produce films with enhanced properties by combining different materials in a three-layer structure: A/B/A. Here’s an in-depth introduction to this advanced machinery.

Advantages of ABA Blown Film Extrusion Line

1.Cost Efficiency - Utilizing More Recycled Materials

In addition to producing stronger films, ABA blown film extruders enable manufacturers to incorporate a higher percentage of recycled materials and at least 50-60% calcium carbonate compounds (CaCO3) into their mixtures. This capability is particularly advantageous when producing thicker films, as it significantly reduces material costs while maintaining high film quality. The resulting films are shiny on the surface and excellent for sealing, even with a high proportion of recycled content.

2.Flexibility

This extrusion line can produce films for various applications, including packaging, agricultural films, and industrial films, thanks to its ability to handle a wide range of materials and thicknesses. Specifically, it is suitable for producing T-shirt bags, garbage bags, and stretch films, providing durability and cost-effectiveness in these common applications.

3.Enhanced Properties

By combining different materials, the ABA film can achieve superior mechanical, optical, and barrier properties. For example, the core layer can provide strength while the outer layers offer clarity or UV protection.

4.Improved Performance

The three-layer structure can improve film performance in terms of puncture resistance, tear resistance, and load-bearing capacity.

What's the Difference Between ABA and a Single Blown Film Machine?

| Feature | ABA Blown Film Line | Single-Layer Blown Film Line |

|---|---|---|

| Number of Layers | Three layers (A/B/A) | Single layer |

| Material Usage | Uses different materials for outer layers (A) and core layer (B) | Uses the same material for the entire film |

| Cost Efficiency | More cost-effective by using less expensive materials in the core | Generally higher material costs as the same material is used throughout |

| Film Properties | Superior mechanical strength, clarity, and barrier properties due to layered structure | Basic film properties with a uniform material composition |

| Versatility | Versatile for various applications, including high-quality packaging and specialty films | Limited to basic film applications, often for simple packaging |

| Applications | T-shirt bags, garbage bags, agricultural films, stretch films | Basic packaging films, simple industrial uses |

| Complexity and Maintenance | More complex with three extruders and a die head for multiple layers | Simpler design with only one extruder and a single die head |

| Film Thickness Adjustment | Allows for production of films with varying thicknesses for different applications | Limited flexibility in film thickness adjustments |

| Film Quality | Can produce high-quality films with specific properties for various applications | Produces standard films without advanced features |

Conclusion

The ABA blown film extrusion line provides significant advantages in cost, flexibility, and film properties. As a professional machine manufacturer, we ensure our ABA extrusion lines are equipped with the latest technology, robust construction, and user-friendly interfaces to meet the diverse needs of the plastic manufacturing industry. Whether you’re producing packaging films, agricultural films, or industrial films, our ABA blown film extrusion line offers the efficiency and reliability required for high-quality film production.

Contact Us Today

If you are interested in learning more about our ABA blown film extrusion line, please contact us today. Our experienced team is ready to assist you in selecting the right solution for your specific needs.

Additional Resources

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]